What are the guidelines for safely operating the wipe packaging machine in different environmental conditions?

On February 28, 2024 by Eli Stewart With 0 Comments

- Blogging

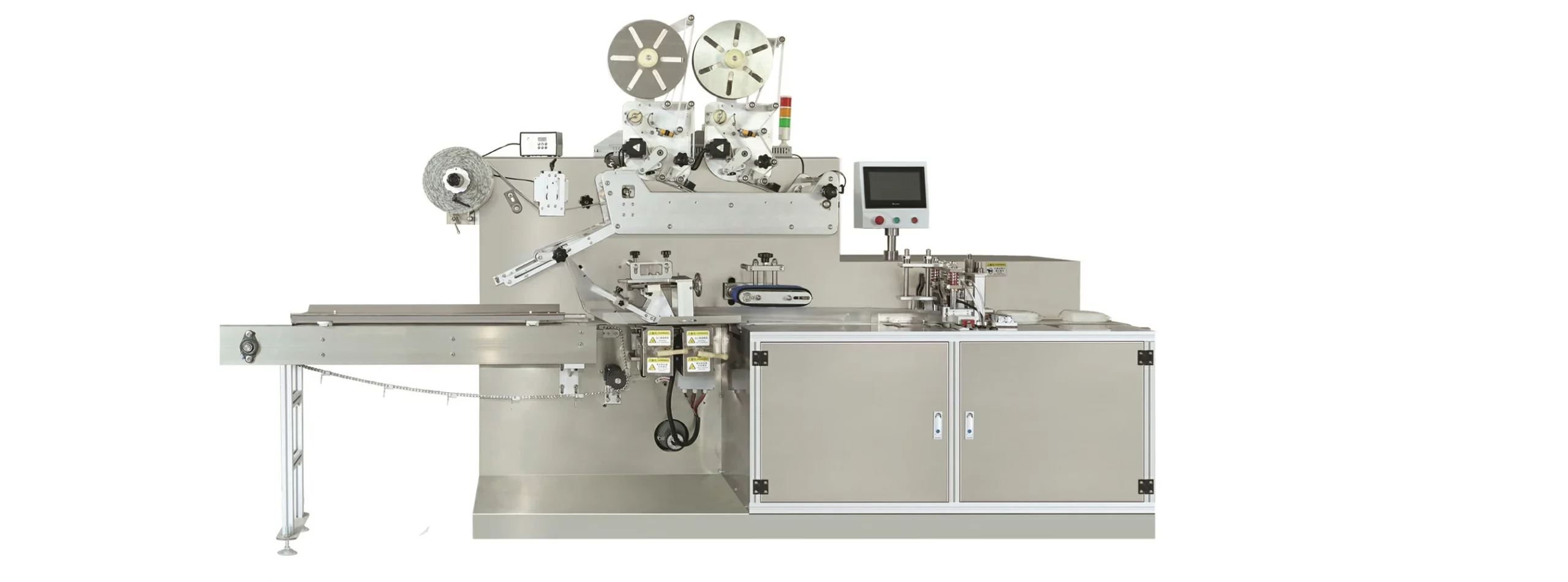

Safely operating a wipe packaging machine in different environmental conditions requires adherence to specific guidelines to ensure the well-being of operators, maintain equipment integrity, and preserve product quality.

Here are some general guidelines:

- Environmental Assessment: Conduct a thorough assessment of the operating environment to identify potential hazards or challenges that may affect machine performance or operator safety. Consider factors such as temperature fluctuations, humidity levels, dust or debris, and air quality.

- Machine Location: Install the wipe packaging machine in a clean, well-ventilated area with stable environmental conditions. Avoid placing the machine near sources of heat, moisture, or airborne contaminants that could compromise performance or product quality.

- Climate Control: If operating in extreme temperatures or humidity levels, consider implementing climate control measures such as air conditioning, heating, or dehumidification to maintain optimal working conditions for both personnel and equipment.

- Equipment Protection: Install protective barriers or enclosures around the machine to shield it from environmental elements such as dust, moisture, or debris. Use dust covers or air filtration systems to prevent contaminants from entering sensitive components.

- Operator Comfort: Provide operators with appropriate personal protective equipment (PPE) and ergonomic accessories to ensure their comfort and safety in different environmental conditions. This may include temperature-appropriate clothing, respirators, gloves, or eye protection.

- Machine Maintenance: Increase the frequency of machine maintenance and inspection in environments with harsh or fluctuating conditions. Regularly clean and lubricate machine components to prevent corrosion, rust, or damage caused by environmental exposure.

- Material Selection: Choose packaging materials that are resistant to environmental factors such as moisture, UV exposure, or temperature variations. wet wipe cologne wipe packaging machine Ensure that packaging materials maintain their integrity and barrier properties under different environmental conditions.

- Operator Training: Provide comprehensive training to operators on how to safely operate the wipe packaging machine in various environmental conditions. Train them to recognize potential hazards and take appropriate precautions to mitigate risks.

- Emergency Preparedness: Develop emergency response procedures specific to different environmental conditions, such as power outages, extreme weather events, or environmental contamination. Ensure that operators are trained in emergency procedures and know how to respond effectively to unexpected situations.

- Regulatory Compliance: Ensure compliance with regulatory standards and guidelines related to workplace safety, environmental protection, and product quality assurance. Stay informed about relevant regulations and update procedures accordingly to meet compliance requirements.

- Continuous Monitoring: Implement a system for continuous monitoring of environmental conditions and machine performance. Use sensors, alarms, or monitoring systems to detect changes in temperature, humidity, or other environmental factors that may affect machine operation.

- Documentation and Review: Keep detailed records of environmental conditions, machine performance, maintenance activities, and any incidents or issues encountered during operation. Regularly review and analyze this data to identify trends, address potential problems, and improve operational practices.

By following these guidelines, operators can safely and effectively operate a wipe packaging machine in different environmental conditions, ensuring the integrity of the product and the well-being of personnel. Adapting procedures and practices to suit specific environmental challenges is essential for maintaining consistent production quality and efficiency.

Comments are Disabled