How is the folding and packaging of the finished sanitary napkin managed?

The folding and packaging of finished sanitary napkins involve a series of automated processes in a sanitary napkin production line. These processes are designed to ensure efficiency, accuracy, and the delivery of high-quality products to consumers.

Here’s an overview of how the folding and packaging of sanitary napkins are typically managed:

Folding Process:

- Automatic Folding Mechanism:

- Once the sanitary napkins are manufactured, they move along the production line to an automatic folding mechanism. This mechanism is designed to fold the napkins into the desired shape and size.

- Fold Configuration Adjustment:

- The folding mechanism is adjustable to accommodate different fold configurations based on the product specifications. This adjustment ensures flexibility in meeting various market demands.

- Quality Control Stations:

- Quality control sensors and cameras are strategically placed to inspect the folded napkins. These stations check for uniformity in the fold, proper alignment, and any defects that may have occurred during the folding process.

- Rejection Mechanism:

- If any folded napkins do not meet the quality standards, a rejection mechanism may be in place to remove them from the production line. This helps maintain the overall quality of the packaged products.

- Transfer to Packaging Area:

- After passing the quality control checks, the folded sanitary napkins are transferred to the packaging area. China sanitary napkin production line factories Conveyor systems or robotic arms are commonly used to facilitate the smooth transition between production stages.

Packaging Process:

- Product Orientation and Stacking:

- In the packaging area, the folded sanitary napkins are oriented and stacked according to the predetermined arrangement for packaging. This is often done with the help of automated stacking mechanisms.

- Packaging Material Feeding:

- Packaging materials, such as polyethylene film or other types of wrappers, are fed into the packaging machine. The packaging material is typically stored in rolls, and an automatic unwinding system facilitates a continuous supply.

- Sealing and Closing:

- The packaging machine seals the edges of the packaging material to encase the stacked sanitary napkins securely. Depending on the packaging design, the machine may use heat sealing, ultrasonic sealing, or other sealing methods.

- Barcode and Labeling (Optional):

- In some production lines, barcode labels or other product information may be added to the packaging. This information can be important for inventory management, traceability, and consumer information.

- Quality Control at Packaging Stage:

- Quality control mechanisms are integrated into the packaging line to inspect the packaged sanitary napkins. This includes checks for proper sealing, accurate product count, and adherence to packaging specifications.

- Batch Coding (Optional):

- Batch coding, which involves marking the packaging with a unique code for traceability, may be implemented. This is particularly important for quality control and tracking in the event of a product recall.

- Cartoning (Optional):

- In some cases, the individually packaged sanitary napkins are further placed into cartons for bulk packaging. Automated cartoning machines may be employed for this additional packaging step.

- Palletizing:

- Finished and packaged sanitary napkin boxes or cartons are often palletized for easy handling, storage, and transportation. Automated palletizing systems or robotic arms may be used for efficient pallet stacking.

- Final Inspection:

- A final inspection may be conducted on the palletized products before they are sent to the warehouse or distribution. This ensures that the entire batch meets quality standards and is ready for shipment.

By integrating automation, quality control measures, and efficient handling systems, manufacturers can ensure the smooth and precise folding and packaging of sanitary napkins, meeting market demands and delivering a reliable and hygienic product to consumers.

Precision Cultivation: China Ebb and Flow Tables Revolutionizing Hydroponics

As the demand for efficient and precise cultivation methods continues to rise, hydroponics has emerged as a game-changer in modern agriculture. Ebb and flow tables, a crucial component of hydroponic systems, play a pivotal role in providing optimal conditions for plant growth. China, a global hub for agricultural innovation, has positioned itself as a leading manufacturer of ebb and flow tables. In this article, we explore the significance of China’s ebb and flow tables, examining their features, benefits, and the transformative impact they have on hydroponic farming.

Understanding Ebb and Flow Tables:

Ebb and flow tables, also known as flood and drain tables, are a fundamental element of hydroponic systems. These tables consist of a flat, elevated surface with a built-in drainage system. The hydroponic plants are placed in containers or growing media on the tables, and nutrient-rich water is periodically flooded onto the surface before receding, allowing for the efficient delivery of water and nutrients to the plants.

Key Features of China Ebb and Flow Tables:

- Durable Construction:

China’s ebb and flow tables are often constructed from durable and corrosion-resistant materials such as high-grade plastics or metals. This ensures the longevity of the tables in hydroponic environments, where they come into regular contact with nutrient solutions. - Optimized Water Distribution:

The design of these tables facilitates even and efficient water distribution to the plants. During the flooding phase, the nutrient-rich water is evenly spread across the table, allowing the growing media or containers to absorb the necessary nutrients before drainage. - Modular and Scalable Designs:

China’s manufacturers provide modular and scalable designs for ebb and flow tables. Growers have the flexibility to expand their hydroponic systems by adding additional tables, creating a scalable and adaptable setup to accommodate the evolving needs of their crops. - Precise Timing Control:

The ebb and flow tables from China are equipped with precise timing controls for flooding and draining cycles. This precision allows growers to tailor the watering schedule to the specific requirements of different plant varieties, promoting optimal growth conditions. - Easy Maintenance:

These tables are designed for easy maintenance, with accessible drainage systems and smooth surfaces that simplify cleaning. The user-friendly design ensures that growers can efficiently manage the tables, promoting a hygienic and disease-free environment.

The Impact of China Ebb and Flow Tables on Hydroponic Farming:

- Enhanced Nutrient Uptake:

Ebb and flow tables ensure enhanced nutrient uptake by providing a consistent supply of water and nutrients directly to the root zones of plants. This controlled delivery system promotes vigorous growth and increased nutrient absorption. - Improved Oxygenation:

The periodic flooding and draining cycles of ebb and flow tables contribute to improved oxygenation of the root zone. As the water drains away, it creates pockets of air around the roots, preventing waterlogging and promoting oxygen absorption—an essential factor for healthy root development. - Space Efficiency:

Ebb and flow tables maximize space efficiency within hydroponic systems. The flat, elevated surface allows for a higher plant density, optimizing the use of available growing space and increasing overall productivity. - Reduced Water Usage:

The controlled watering cycles of ebb and flow tables contribute to reduced water usage in hydroponic systems. This efficiency is especially critical in water-scarce regions, making hydroponic farming with ebb and flow tables a sustainable choice. - Customizable Growing Environments:

China’s ebb and flow tables offer growers the ability to create customizable growing environments. By adjusting flood and drain intervals, growers can cater to the specific needs of different crops, facilitating the cultivation of a diverse range of plants within the same hydroponic system.

China Leadership in Hydroponic Innovation:

- Technological Advancements:

China’s manufacturers of ebb and flow tables continually invest in technological advancements. These include innovations in timing controls, material technologies, and automation features to enhance the efficiency and precision of hydroponic systems. - Global Export of Hydroponic Systems:

China’s expertise in hydroponic technology extends to the global market. The export of ebb and flow tables and complete hydroponic systems to countries worldwide demonstrates China’s influence on the evolution of modern agriculture globally. - Collaboration with Agricultural Experts:

Collaboration between Chinese hydroponic manufacturers and agricultural experts ensures that ebb and flow tables align with the latest advancements in the industry. This collaborative approach fosters continuous improvement and innovation.

Considerations When Choosing Ebb and Flow Tables from China:

- Material Quality:

Evaluate the quality of materials used in the construction of ebb and flow tables. Opt for tables made from durable, corrosion-resistant materials to ensure longevity and resilience in hydroponic environments. - Timing Controls and Automation:

Consider the timing controls and automation features integrated into the ebb and flow tables. Precise timing controls and automation contribute to the efficiency and ease of managing hydroponic systems. - Scalability and Modularity:

Assess the scalability and modularity of the ebb and flow tables. Choose tables that offer flexibility for expansion, allowing growers to scale their hydroponic systems as needed. - Ease of Maintenance:

Prioritize ebb and flow tables that are designed for easy maintenance. Features such as accessible drainage systems and smooth surfaces contribute to the cleanliness and hygiene of the hydroponic environment. - Manufacturer Reputation:

Research the reputation of the ebb and flow table manufacturer. Positive customer feedback, testimonials, and a track record of successful installations are indicative of a reliable and reputable supplier.

China’s leadership in manufacturing ebb and flow tables underscores the country’s commitment to driving innovation and sustainability in hydroponic farming. These tables, with their precision watering systems and space-efficient designs, represent a significant advancement in controlled environment agriculture.

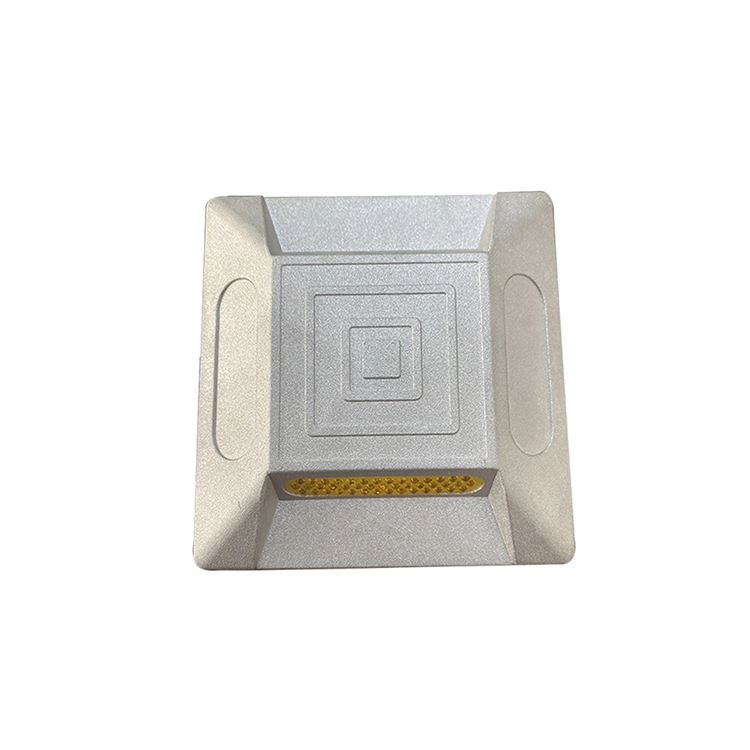

What types of materials are used in the construction of solar road studs for durability?

Solar road studs are constructed using materials that offer durability, resistance to environmental elements, and the ability to withstand the stresses of road use.

Common materials used in the construction of solar road studs include:

- Polycarbonate:

- Polycarbonate is a durable and impact-resistant thermoplastic material often used for the outer shell or lens of solar road studs. It provides excellent clarity and can withstand the physical stresses associated with road conditions.

- Aluminum Alloy:

- Aluminum alloy is commonly used for the body or housing of solar road studs. It offers a combination of strength, corrosion resistance, and light weight. Aluminum helps protect internal components from environmental factors.

- Stainless Steel:

- Stainless steel is used for certain components, such as fasteners, screws, or brackets, to provide corrosion resistance. Stainless steel ensures that these components remain durable and functional in various weather conditions.

- Polymers and Elastomers:

- Various polymers and elastomers are used for seals and gaskets to protect the internal electronics from moisture and dust. These materials help maintain the integrity of the solar road stud in challenging environmental conditions.

- High-Grade Plastics:

- High-grade plastics are used for certain structural components, such as the base or internal supports. These plastics are selected for their durability, Solar Road Stud manufacturers resistance to UV radiation, and ability to withstand temperature variations.

- Tempered Glass:

- Tempered glass is often used for the surface of solar road studs, providing a transparent and scratch-resistant cover. Tempering enhances the glass’s strength and impact resistance, making it suitable for use in road applications.

- Silicone Sealants:

- Silicone sealants are used to create a watertight and weather-resistant seal around the edges of the solar road stud. This helps protect the internal components from moisture and environmental contaminants.

- Epoxy Resins:

- Epoxy resins are used in the adhesive layer that attaches the solar road stud to the road surface. These resins provide a strong bond and help secure the stud in place, ensuring stability and durability.

- UV-Resistant Coatings:

- UV-resistant coatings may be applied to certain surfaces of the solar road stud to protect against the degrading effects of prolonged exposure to sunlight. These coatings help maintain the appearance and functionality of the stud over time.

- Electronic Components:

- High-quality electronic components, including solar panels, rechargeable batteries, and LED lights, are selected for their durability and performance. These components are designed to withstand temperature variations and provide reliable operation over the product’s lifespan.

The combination of these materials ensures that solar road studs can withstand harsh weather conditions, heavy traffic loads, and other environmental challenges. Durability is a critical factor in the design of solar road studs to ensure their long-term effectiveness in enhancing road safety.

How do Solar Road Stud contribute to sustainable and energy-efficient road infrastructure?

Solar road studs contribute to sustainable and energy-efficient road infrastructure through their use of solar power, reducing the reliance on conventional energy sources and minimizing the environmental impact of roadway lighting.

Here are ways in which solar road studs promote sustainability and energy efficiency:

- Solar Power Generation:

- Solar road studs are equipped with solar photovoltaic (PV) cells that capture sunlight and convert it into electrical energy. This process harnesses renewable solar energy, reducing the need for electricity from conventional power sources.

- Off-Grid Operation:

- Solar road studs operate independently of the electrical grid, making them suitable for remote or off-grid locations. This reduces the need for extensive infrastructure to connect them to power sources, contributing to energy efficiency and cost savings.

- Reduced Carbon Footprint:

- By utilizing solar energy, solar road studs help reduce the carbon footprint associated with conventional lighting systems powered by fossil fuels. The use of renewable energy sources aligns with sustainability goals and mitigates environmental impact.

- Low Environmental Impact:

- Solar road studs typically have a low environmental impact during their lifecycle. They do not require excavation for power cables, minimizing disruption to ecosystems. The manufacturing and disposal processes can be designed to be environmentally responsible.

- Energy Storage with Batteries:

- Solar road studs incorporate rechargeable batteries to store excess energy generated during the day. This stored energy is then used to power the studs during periods of low sunlight or at night, ensuring continuous illumination without drawing from the grid.

- Reduced Energy Consumption:

- Traditional roadway lighting systems that rely on grid power can consume significant amounts of energy. Solar road studs use energy-efficient LED lights, which consume less power compared to conventional lighting technologies. This further contributes to energy savings.

- Smart Lighting Controls:

- Some solar road studs are equipped with smart lighting controls, allowing them to adjust brightness levels based on ambient light conditions. This adaptive lighting reduces energy consumption during periods of high natural illumination.

- Long Lifespan and Durability:

- Solar road studs are designed for durability and longevity. Their long lifespan reduces the frequency of replacements, China Solar Road Stud resulting in lower resource consumption and less waste. This contributes to the overall sustainability of the road infrastructure.

- Customizable Lighting Patterns:

- Certain solar road studs offer customizable lighting patterns or flashing modes. This feature allows for optimized use of energy, providing necessary visibility when needed and conserving energy during less critical times.

- Enhanced Safety and Reduced Accidents:

- By improving visibility and delineating road features, solar road studs contribute to enhanced safety. This, in turn, can reduce the likelihood of accidents and the associated environmental impacts, contributing to overall sustainability.

- Adaptability to Renewable Energy Initiatives:

- Solar road studs align with broader renewable energy initiatives and sustainability goals. Their integration into road infrastructure supports the adoption of clean energy technologies within the transportation sector.

By harnessing solar energy and incorporating energy-efficient technologies, solar road studs play a role in creating more sustainable and environmentally friendly road infrastructure. Their use contributes to the reduction of greenhouse gas emissions and dependence on non-renewable energy sources.

China Impact on Agricultural Equipment: Innovations in Grow Rack Manufacturing

China has become a global leader in manufacturing various types of agricultural equipment, playing a significant role in shaping modern farming practices worldwide. Among these innovations are specialized products like grow racks, which have transformed the way crops are cultivated within controlled environments. This article aims to explore China’s role in grow rack manufacturing, its impact on the agricultural sector, and the advancements driving the evolution of these systems.

China Growing Presence in Agricultural Equipment Manufacturing:

China’s manufacturing prowess extends to various agricultural equipment, including grow racks utilized in controlled environments such as greenhouses and indoor farming setups. The country’s robust manufacturing infrastructure, technological advancements, and cost-effective production capabilities have made it a major hub for supplying innovative agricultural solutions to global markets.

Innovations in Grow Rack Manufacturing:

China’s agricultural equipment manufacturers have been instrumental in developing efficient and customizable grow rack systems. These racks are designed to optimize space utilization, enhance crop growth conditions, and streamline cultivation processes. Through continuous research and development, manufacturers in China have introduced versatile grow racks tailored to different crop types, growth stages, and environmental requirements.

Advantages of China Grow Rack Technology:

- Adaptability and Customization: China’s grow racks are designed to be adaptable, allowing for easy customization to suit various plant species and cultivation methods.

- Space Optimization: These racks maximize vertical growing space, enabling growers to cultivate more plants within limited areas, thus increasing overall productivity.

- Resource Efficiency: Innovations in these systems optimize resource utilization, including water, nutrients, and light, contributing to sustainable and cost-effective farming practices.

- Technology Integration: Some of the advanced grow racks from China integrate technology for precise environmental control, automation, and monitoring, enhancing crop management efficiency.

China’s Contribution to Global Agriculture:

The advancements in grow rack technology exemplify China’s contribution to the global agricultural landscape. By offering efficient and cost-effective solutions, China’s agricultural equipment manufacturers have empowered farmers and horticulturists worldwide to enhance crop cultivation, improve yields, and support sustainable farming practices.

Future Developments and Expectations:

Continued research and development in grow rack technology are expected to lead to further innovations. This might include advancements in automation, smart sensors, and eco-friendly materials, aiming to improve efficiency, reduce environmental impact, and meet the evolving needs of the agricultural industry globally.

China’s prominence in agricultural equipment manufacturing, including innovative grow rack systems, highlights the country’s commitment to advancing farming practices worldwide. The continuous evolution of these systems, driven by technological innovation and a focus on sustainability, signifies a promising future for global agriculture, fostering increased productivity and efficient crop cultivation.

Elevating Lip Care: Unveiling the Power of Private Label Moisturizing Lip Balms

Private label moisturizing lip balms are revolutionizing the beauty industry, offering a personalized touch to lip care routines while ensuring hydration and nourishment for luscious, healthy lips. These balms, infused with moisturizing agents and customizable through private labeling, provide an avenue for businesses to offer tailored lip care solutions. This article aims to explore the significance, advantages, considerations, and the transformative impact of private label moisturizing lip balms in catering to individual preferences and brand uniqueness.

The Significance of Private Label Moisturizing Lip Balms

Personalized Branding:

Private labeling allows businesses to customize lip balms with their branding, creating a unique identity and customer loyalty.

Custom Formulations:

Tailoring the formulation enables businesses to address specific concerns, offering enhanced moisture and nourishment for lips.

Advantages and Features

Hydration and Nourishment:

Moisturizing ingredients like shea butter, oils, and vitamins keep lips hydrated, soft, and protected from dryness.

Customizable Labeling:

Private labeling enables businesses to imprint their logo, design, or messaging, creating a distinctive product identity.

Brand Differentiation and Versatility

Brand Recognition:

Private label lip balms promote brand visibility and recognition, distinguishing businesses in a competitive market.

Diverse Offerings:

Businesses can create a range of flavors, formulations, and packaging options to cater to various consumer preferences.

Considerations for Private Label Lip Balms

Quality Assurance:

Ensure lip balms are crafted from high-quality, skin-friendly ingredients to maintain customer satisfaction and trust.

Compliance and Regulations:

Adhere to regulatory standards and certifications to guarantee the safety and efficacy of the lip balm formulations.

Moisturizing lip balm private label represent a convergence of customized skincare and brand identity, offering businesses a platform to provide tailored lip care solutions. Beyond nourishment and hydration, these balms empower businesses to create distinct brand personas and cater to diverse consumer needs. When considering private label lip balms, prioritize quality formulations and compliance while leveraging customization options to create a unique brand identity. By embracing private label moisturizing lip balms, businesses can establish a strong presence in the beauty industry, offering consumers personalized lip care experiences while fostering brand loyalty. Remember, the allure of private label lip balms lies in their ability to marry customization with quality, offering consumers personalized skincare solutions under a trusted brand umbrella.

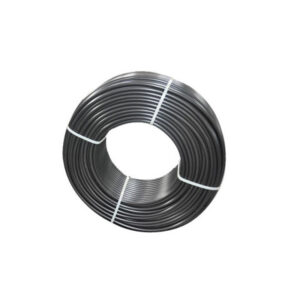

Are there economic benefits to using drip pipe for large-scale agriculture?

Absolutely, using drip pipes in large-scale agriculture offers several economic advantages:

- Water Savings: Drip pipes are highly efficient in water usage, delivering water directly to the root zone of plants. This efficiency leads to significant water savings compared to traditional irrigation methods, reducing water costs for farmers.

- Reduced Labor Costs: Once installed, drip irrigation systems with drip pipes require less labor for operation and maintenance compared to labor-intensive methods like manual watering or moving sprinklers. This reduction in labor can lead to cost savings for agricultural operations.

- Increased Yield and Quality: Drip pipes ensure plants receive consistent and optimal watering, leading to improved crop yields and better quality produce. Higher yields and better-quality crops often translate to increased profits for farmers.

- Fertilizer Efficiency: Drip irrigation systems allow for precise delivery of fertilizers directly to the root zone. This targeted application enhances fertilizer efficiency, reducing the amount of fertilizer needed and cutting costs associated with fertilization.

- Energy Savings: Drip irrigation systems typically require less energy for water distribution compared to methods like center pivot irrigation or flooding. Lower energy consumption leads to reduced operational costs for farmers.

- Reduced Weed Control Costs: By delivering water directly to the plant roots, drip pipes help reduce weed growth between rows. This can result in lower expenses for weed control measures and labor.

- Long-Term Investment: While the initial setup cost of installing drip irrigation systems with drip pipes can be higher, they often prove to be a long-term investment. china drip pipe Their durability and efficiency contribute to cost savings over time, outweighing the initial investment.

- Land Optimization: Drip irrigation systems can allow for more efficient use of available land by enabling precise placement of water and nutrients. This optimization of land use can lead to increased production per unit area and higher profitability.

- Crop Diversification and Season Extension: Drip irrigation systems, with their precise control over water delivery, allow for crop diversification and extension of growing seasons in certain climates. This flexibility can open opportunities for higher-value crops and increased profits.

- Risk Mitigation: The ability of drip irrigation to provide consistent and controlled watering helps mitigate risks associated with drought or irregular rainfall patterns, safeguarding against potential crop losses and protecting farmers’ incomes.

Overall, the economic benefits of using drip pipes in large-scale agriculture include cost savings in water, labor, energy, fertilizers, improved yields, and crop quality, making it a financially viable and profitable investment for many farming operations.

Can a drip pipe be integrated with other farming techniques, such as crop rotation?

Yes, drip pipes can be integrated with various farming techniques, including crop rotation, to enhance overall agricultural practices.

Here’s how drip irrigation systems, including drip pipes, can complement and support crop rotation:

- Adaptability to Different Crops: Drip irrigation systems are adaptable and versatile, allowing farmers to easily switch between different crops within a rotation cycle. The flexibility of drip pipes enables precise watering for various crops with different water requirements.

- Optimized Watering for Rotation Crops: Different crops in a rotation sequence might have varying water needs. Drip pipes enable farmers to adjust watering schedules and amounts according to each crop’s requirements, ensuring optimal growth throughout the rotation cycle.

- Enhanced Soil Health: Crop rotation aims to improve soil fertility and structure. Drip irrigation systems, by delivering water directly to the root zone, support healthier soil conditions. They prevent soil erosion, minimize compaction, and reduce nutrient leaching, contributing to improved soil health during rotation cycles.

- Efficient Nutrient Delivery: Drip irrigation systems can incorporate fertigation, allowing precise delivery of nutrients along with water directly to plant roots. This feature supports the nutritional needs of crops in rotation, enhancing their growth and health.

- Reduced Disease Spread: Crop rotation helps prevent the buildup of pests and diseases associated with specific crops. Drip irrigation, by avoiding overhead watering, reduces moisture on plant leaves, minimizing the spread of foliar diseases during rotations.

- Conserved Water Resources: Drip irrigation systems, including drip pipes, are highly efficient in water usage. During crop rotation, the controlled and targeted water delivery helps conserve water while meeting the varying needs of different crops in the rotation cycle.

- Season Extension and Timing: Drip irrigation can extend growing seasons or facilitate off-season cultivation by providing consistent and controlled watering. This flexibility aligns with the timing requirements of different crops in rotation.

- Increased Productivity: Properly managed drip irrigation systems can contribute to increased productivity during crop rotations. The precise watering, optimized nutrient delivery, and improved soil health can result in better yields and overall success across the rotation cycle.

Integrating drip pipes and drip irrigation systems with crop rotation practices allows for better water management, improved soil health, and optimized growing conditions for various crops. This integration supports the goals of crop rotation, contributing to sustainable and efficient agricultural practices.

How does a drip tape fittings help control soil erosion?

Drip tape fittings play a role in controlling soil erosion by contributing to the efficient and targeted delivery of water in drip irrigation systems.

Here’s how they can help mitigate soil erosion:

- Precise Water Delivery: Drip tape fittings connect the drip tape (thin-walled tubing with evenly spaced drip emitters) to the main supply line. These fittings ensure a secure connection and control the flow of water to the drip tape.

- Uniform Water Distribution: Properly installed drip tape fittings ensure that water is evenly distributed along the tape. This targeted watering directly to the root zones of plants minimizes surface runoff, preventing excessive water movement that can contribute to soil erosion.

- Reduced Surface Water: Drip irrigation, facilitated by drip tape fittings, applies water at a slow and controlled rate. This slow application reduces the formation of puddles or surface water accumulation, minimizing the erosive forces of rainfall or irrigation.

- Preserved Soil Structure: By delivering water directly to the root zones of plants without excess runoff, drip tape fittings help maintain soil structure. Preserving the integrity of the soil structure is crucial in preventing erosion caused by water movement.

- Conserved Soil Moisture: Drip irrigation systems, with the help of drip tape fittings, maintain consistent soil moisture levels. Consistent moisture encourages vegetation growth and root development, which further helps anchor soil and prevents erosion.

- Suitability for Sloped Terrain: Drip tape fittings are adaptable for use on sloped terrain. Their ability to deliver water precisely to plants without excessive surface water makes them suitable for areas prone to soil erosion due to gravity-induced water movement.

- Erosion Control Measures: In combination with other erosion control measures such as mulching, cover cropping, or contour farming, drip tape fittings contribute to a comprehensive strategy for soil erosion prevention.

While drip tape fittings themselves may not solely prevent soil erosion, their role within a well-designed drip irrigation system is crucial. When properly installed and managed, they contribute to efficient water delivery, moisture conservation, and reduced surface runoff, all of which help in controlling and minimizing soil erosion in agricultural settings.

What are the environmental benefits of using drip tape fittings ?

Using drip tape fittings in irrigation systems offers several environmental benefits:

- Water Conservation: Drip tape fittings facilitate precise water delivery directly to the root zone of plants. This targeted watering minimizes water waste by reducing evaporation, runoff, and overspray, leading to significant water savings compared to traditional irrigation methods.

- Reduced Water Pollution: By delivering water directly to plants without excessive runoff, drip tape fittings help minimize the leaching of fertilizers and pesticides into water bodies. This reduces the risk of water pollution and protects local ecosystems.

- Energy Efficiency: Drip irrigation systems, including fittings like drip tapes, are generally more energy-efficient than other irrigation methods. China drip tape fittings Supplier They often require lower pressure and less energy for water distribution, contributing to overall energy conservation.

- Soil Health and Conservation: Precise and controlled water delivery provided by drip tape fittings supports soil health. Consistent moisture levels enhance soil structure, reduce erosion, and promote microbial activity, contributing to long-term soil conservation.

- Biodiversity Preservation: By optimizing water usage and reducing runoff, drip irrigation systems using fittings help preserve natural habitats and biodiversity. Conserved water resources and minimized environmental impact support diverse ecosystems.

- Reduced Greenhouse Gas Emissions: The efficient use of water in drip irrigation systems decreases the need for energy-intensive pumping or transportation of water, reducing associated greenhouse gas emissions.

- Less Pressure on Water Sources: With their water efficiency, drip tape fittings contribute to less pressure on freshwater sources. By maximizing the use of available water resources, they help sustainably manage water scarcity issues.

- Mitigation of Salinity and Soil Degradation: Drip irrigation, facilitated by drip tape fittings, helps manage soil salinity by providing controlled and consistent watering, which prevents salt accumulation in the soil.

- Promotion of Sustainable Agriculture: Drip tape fittings support sustainable agricultural practices by optimizing resource use, reducing environmental impact, and contributing to the long-term viability of farming operations.

Overall, the environmental benefits of using drip tape fittings in irrigation systems include water conservation, reduced pollution, enhanced soil health, energy efficiency, biodiversity preservation, and the promotion of sustainable agriculture practices, making them an environmentally friendly choice for irrigation in various settings.

Lip Gloss vs. Lip Balm: Understanding the Differences and Benefits for Your Lips

Lip glosses and lip balms stand as indispensable components in the realm of lip care and beauty, each offering distinct benefits catering to various lip needs. Understanding the differences between these two products can help you choose the ideal solution for nourished, healthy, and glamorous lips.

Lip Gloss: Amplifying Glamour and Shine

Lip glosses have long been cherished for their ability to enhance the lips with a glossy finish, imparting shine and allure to one’s appearance. These products are crafted with specific features that set them apart:

Features of Lip Gloss:

- Glossy Finish: Lip glosses offer a shiny and reflective appearance, adding dimension and plumpness to the lips.

- Variety in Finishes: Available in different finishes such as sheer, glittery, metallic, or high-shine glosses, catering to diverse preferences and occasions.

Benefits of Lip Gloss:

- Enhanced Appearance: Lip glosses instantly add a luminous and glamorous touch to the lips, making them appear fuller and more defined.

- Statement Looks: Ideal for creating bold or subtle looks, lip glosses can be worn alone or layered over lipstick to amplify the color and shine.

Lip Balm: Nurturing and Protecting Lips

Lip balms, on the other hand, prioritize lip care, hydration, and protection, offering a more subtle yet effective solution for maintaining lip health:

Features of Lip Balm:

- Hydrating Formula: Lip balms are formulated with emollients, natural oils, and butters, providing deep hydration to nourish and protect the lips.

- Protective Shield: They form a barrier against external factors like dry air, wind, and UV rays, safeguarding lips from damage.

Benefits of Lip Balm:

- Nourishment: Lip balms offer intense moisturization, preventing dryness, chapping, and keeping lips soft and supple.

- Daily Lip Care: Ideal for everyday use, lip balms are suitable for anyone seeking continuous hydration and protection.

Choosing the Right Lip Product

- Occasion and Preference: Lip glosses are perfect for adding shine and glamour for special events or to elevate a makeup look, while lip balms are essential for everyday lip care and maintenance.

- Combination Use: Many individuals prefer using both lip gloss and lip balm, applying lip balm for hydration and protection and layering lip gloss for added shine and style.

Lip glosses and lip balms serve unique yet complementary purposes in lip care and beauty. While lip glosses enhance appearance with shine and allure, lip balms prioritize lip health, providing hydration, protection, lip gloss lip balm and nourishment.

Selecting between lip gloss and lip balm often depends on personal preferences, occasions, and the desired outcome—whether seeking a glossy and glamorous finish or focusing on lip care and moisture. Incorporating both into a lip care routine ensures that lips remain both stylish and healthy, striking the perfect balance between glamour and nourishment.

Unveiling the Advantages of pneumatic actuator butterfly valve in Commercial Plumbing Systems

Pneumatic actuator butterfly valve offer several advantages when used in commercial plumbing systems. Here are the key advantages of using pneumatic actuator butterfly valves in such applications:

Efficient Flow Control:

Pneumatic actuator butterfly valves provide efficient flow control in commercial plumbing systems. The butterfly valve design allows for quick and precise throttling or shut-off of the flow. The actuator, powered by compressed air, enables fast and reliable operation, allowing for immediate adjustments to flow rates as needed.

Fast Response Time:

Pneumatic actuators offer fast response times, ensuring rapid opening and closing of the butterfly valve. This quick response is crucial in commercial plumbing systems where timely flow control is required. The pneumatic actuation system allows for near-instantaneous adjustments, helping to maintain optimal flow conditions and respond promptly to changing demands.

Remote Operation and Automation:

Pneumatic actuator butterfly valves can be easily integrated into automated control systems. The pneumatic actuator can be connected to a central control system, enabling remote operation and automation. This feature allows for efficient management of multiple valves in a commercial plumbing system, enhancing overall system control and reducing labor requirements.

Compact and Lightweight Design:

Pneumatic actuator butterfly valves have a compact and lightweight design, making them space-efficient and easy to install. Their compact size requires less space in plumbing systems, allowing for more flexible installation options and reducing the overall footprint of the system.

Reliable Sealing Performance:

Butterfly valves equipped with pneumatic actuators provide reliable sealing performance. The resilient seat of the butterfly valve ensures a tight shut-off, preventing leakage and minimizing the risk of water or fluid loss. This sealing performance is essential in commercial plumbing systems to maintain proper flow control and prevent wastage or damage to the plumbing infrastructure.

Corrosion Resistance:

Pneumatic actuator butterfly valves are available in a variety of materials, including stainless steel, which provides excellent corrosion resistance. This feature is particularly important in commercial plumbing systems where exposure to water and chemicals may lead to corrosion over time. The corrosion resistance ensures the longevity and reliability of the valves, reducing the need for frequent maintenance or replacement.

Versatility:

Pneumatic actuator butterfly valves offer versatility in commercial plumbing systems. They can handle a wide range of fluids, including water, gases, and chemicals, making them suitable for various applications. Whether it’s controlling water flow in a building’s plumbing network or managing fluid circulation in HVAC systems, pneumatic actuator butterfly valves can adapt to different requirements.

Energy Efficiency:

Pneumatic actuators are energy-efficient, as they require minimal power to operate. The compressed air used to actuate the valves is readily available in many commercial settings, making them a cost-effective choice. Additionally, the fast response and precise flow control of pneumatic actuator butterfly valves can contribute to overall energy savings by optimizing system performance and reducing unnecessary flow or pressure fluctuations.

In summary, pneumatic actuator butterfly valves offer advantages such as efficient flow control, fast response time, remote operation and automation capabilities, compact design, reliable sealing performance, corrosion resistance, versatility, and energy efficiency. These features make them well-suited for use in commercial plumbing systems, ensuring effective flow control and reliable operation.