How do these machines contribute to increased efficiency and productivity in block manufacturing?

On December 4, 2023 by Eli Stewart With 0 Comments

- Blogging

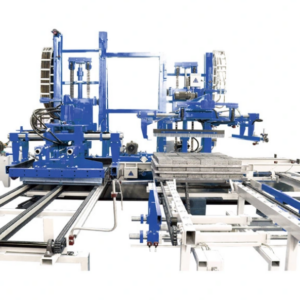

Automatic block making machines significantly contribute to increased efficiency and productivity in block manufacturing through several key aspects:

- High Production Capacity: These machines have high production capacities, capable of manufacturing a large volume of blocks in a shorter timeframe compared to manual or semi-automatic methods.

- Consistent Quality: Automation ensures consistent quality in block production. Uniformity in size, shape, and composition leads to better structural integrity and aesthetic appeal, minimizing rejections and improving efficiency.

- Reduced Labor Dependency: Automation reduces the need for manual labor in block manufacturing. Machines handle various tasks, minimizing human intervention in repetitive or physically demanding activities, leading to cost savings and improved safety.

- Customization and Flexibility: Many machines allow for customization in block sizes, shapes, or designs. This flexibility accommodates diverse architectural requirements, offering a range of design possibilities without compromising efficiency.

- Optimized Material Usage: Automated systems precisely measure and control raw material usage, minimizing waste and optimizing material consumption. This efficiency reduces costs and minimizes environmental impact.

- Streamlined Operations: These machines streamline the production process, offering a more organized and efficient workflow. This streamlining contributes to smoother project management and quicker construction progress.

- Quick Changeovers: Some machines enable rapid mold changes or adjustments, allowing for swift transitions between different block sizes, shapes, or designs. This flexibility minimizes downtime and enhances operational efficiency.

- Integrated Quality Control: Automation includes in-line quality control mechanisms that inspect produced blocks in real-time. Defective products can be identified and removed automatically, ensuring a higher percentage of usable output.

- Data Monitoring and Analysis: Automated systems collect and analyze production data in real-time. This information helps identify inefficiencies, allowing for continuous process improvement to enhance efficiency.

- Energy Efficiency: Modern automated machines are designed to operate efficiently, consuming minimal energy while maintaining high productivity. Energy-efficient systems contribute to reduced operational costs and environmental impact.

By integrating automation, precision, and efficiency into the block manufacturing process, these machines significantly enhance productivity, minimize waste, reduce operational costs, and contribute to the timely completion of construction projects.

How does automation play a role in the operation and efficiency of these machines?

Automation plays a fundamental role in the operation and efficiency of block making machines, influencing various aspects of their functionality:

- Consistency and Precision: Automation ensures consistent quality and precise measurements in block production. Automated systems control parameters such as material proportions, compaction, and shaping, resulting in uniformity across all produced blocks.

- Increased Speed and Productivity: Automation enables machines to operate continuously and efficiently, significantly increasing the rate of block production compared to manual methods. This automation boosts overall productivity.

- Reduced Labor Dependency: Automation minimizes the reliance on manual labor. Machines handle various tasks, reducing human intervention in repetitive or physically demanding activities, leading to cost savings and improved safety.

- Optimized Material Usage: Automated systems precisely measure and control raw material usage, minimizing waste and optimizing material consumption. china brick making machine This efficiency reduces costs and minimizes environmental impact.

- Integrated Quality Control: Automation includes in-line quality control mechanisms that inspect produced blocks in real-time. Defective products can be identified and removed automatically, ensuring a higher percentage of usable output.

- Data Monitoring and Analysis: Automated systems collect and analyze production data in real-time. This information helps identify inefficiencies, allowing for continuous process improvement and efficiency enhancement.

- Remote Monitoring and Control: Advanced automation allows for remote monitoring and control of machines. Operators can oversee operations from a distance, address issues promptly, and make real-time adjustments, minimizing downtime.

- Energy Efficiency: Modern automated machines are designed to operate efficiently, consuming minimal energy while maintaining high productivity. Energy-efficient systems contribute to reduced operational costs and environmental impact.

- Consistency in Maintenance: Automated systems may have built-in maintenance alerts or predictive maintenance features. These systems detect issues early, allowing for proactive maintenance scheduling, ensuring continuous machine operation.

Overall, automation streamlines processes, improves accuracy, enhances productivity, reduces labor costs, and contributes to higher-quality block production. It transforms the manufacturing process, making it more efficient, reliable, and adaptable to various production needs.

Comments are Disabled